-

Phone:

+1 (905) 565-5760

- Address:

5 - 2650 Meadowvale Blvd. - Mississauga, ON L5N 6M5

Canada

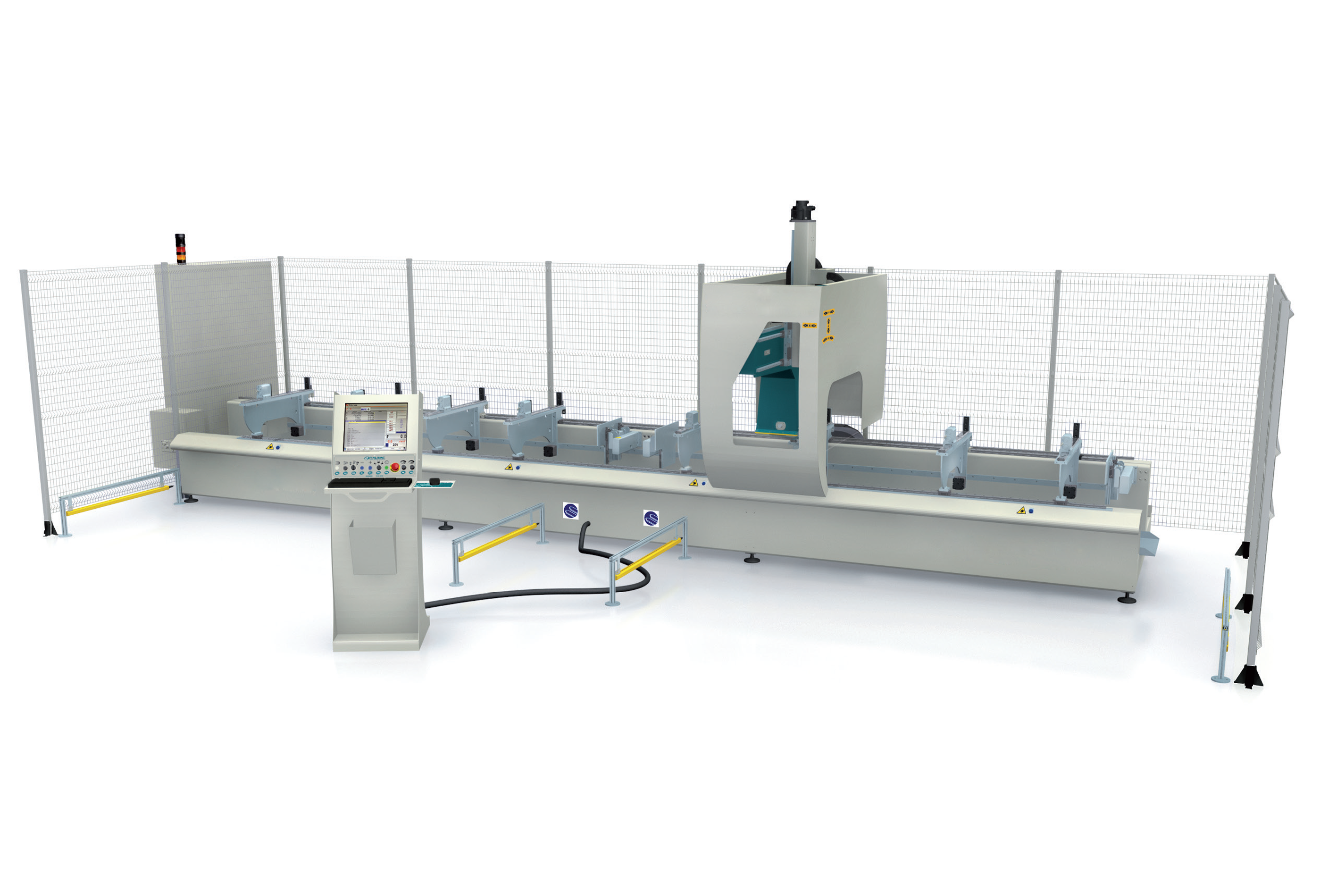

P3 Machining Center

P3 is a 3-Axis CNC machining center with moving portal, especially designed for milling, drilling, threading and cutting bars or workpieces made of aluminium, PVC, light alloys and steel.

Technical Features

- Main structures made of electro-welded steel, normalized and worked with CNC machine tools.

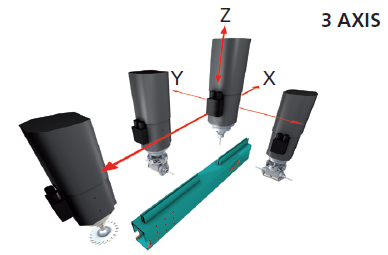

- 3-Axis movement controlled by high-precision brushless servomotors.

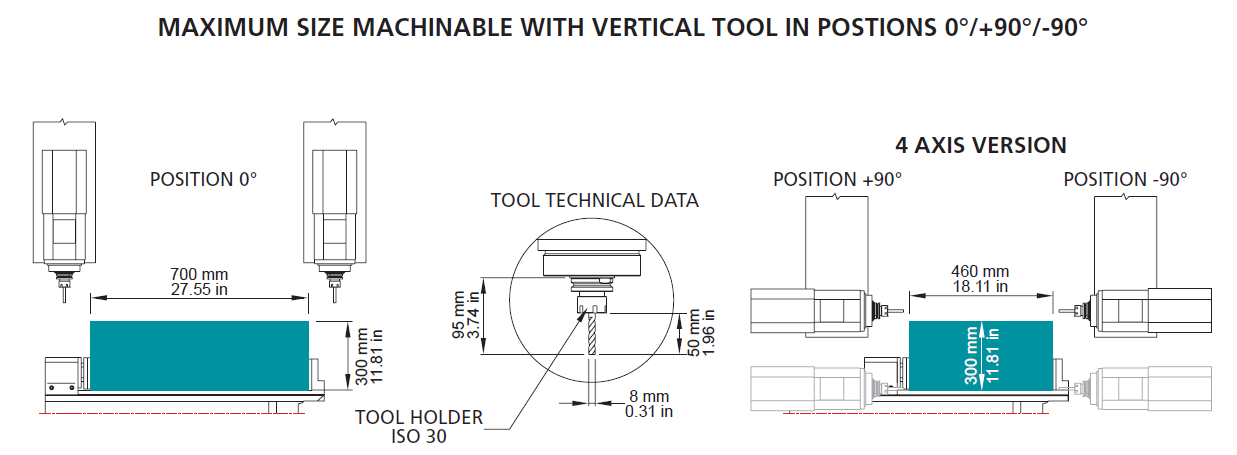

- Electric spindle (5,5 kW in S1), with ISO 30 tool connection suitable for material removal processes during milling and drilling operations.

- Tool magazine holding up to 8 tools, placed on the back side of the moving portal.

- Clamps movement automatically set, controlled by CNC.

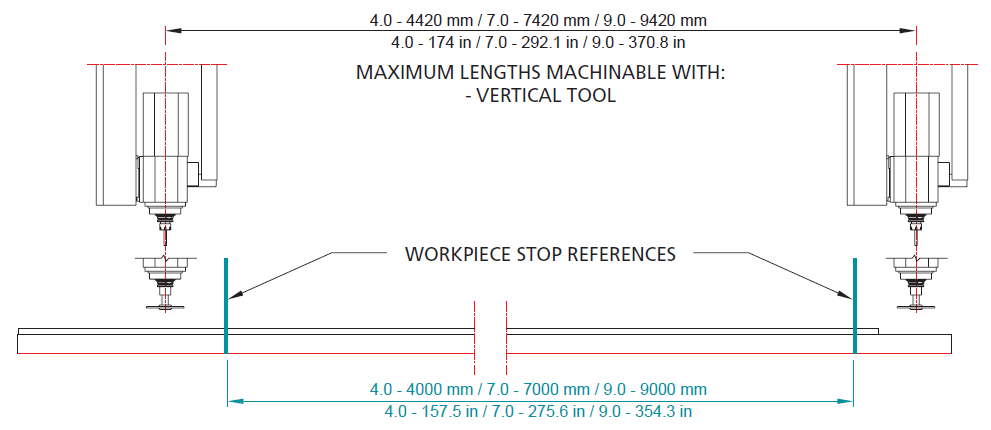

- Standard versions 4, 7 and 9 meters.

- Double working area (version 7 and 9 meters).

- Chip conveyor plate

- Safety light curtains system located in front of the machine

- Safety guards in electro-welded net on the three sides of the machine

Specifications

- X AXIS LONGITUDINAL: 4420 – 7420 – 9420 mm (174 – 292 – 371 in)

- Y AXIS CROSS: 1140 mm (44.9 in)

- Z AXIS VERTICAL: 600 mm (23.6 in)

- AXIS POSITIONING SPEED: X 100 m/min;Y 55 m/min; Z 30 m/min

- AXIS ACCELERATION: X 2 m/sec²; Y 2 m/sec²; Z 2 m/sec²

- TOOL MAGAZINE CAPACITY: 8 positions

- MAXIMUM MILLING BLADE DIAMETER: 120 mm (4.72 in)

- NUMBER OF STANDARD VICES: 4 (4.0 version); 8 (7.0 – 9.0 version)

- VICES POSITIONING: automatic

- NUMBER OF STOP REFERENCES STANDARD: 1 pneumatic (4.0 version); 2 pneumatic (7.0 – 9.0 version)

- VOLTAGE: 400 V triphase – 50/60 Hz

- SPINDLE MOTOR POWER S1: 5,5 kW

- ADJUSTABLE ELECTRO SPINDLE SPEED: 0-24000 rpm

- TOOL HOLDER: ISO 30

- SPINDLE COOLING SYSTEM: Electric fan

- OPERATING PRESSURE: 7 bar

- TOTAL INSTALLED POWER: 10 kW

- OVERALL DIMENSIONS (DxWxH) mm – WEIGHT kg: 6300x3100x2400 mm – 2300kg; 9800x3100x2400 mm – 3200 kg; 11300x3100x2400 mm – 3600 kg

- OVERALL DIMENSIONS (DxWxH) in – WEIGHT lb: 248x122x95 in – 5060lb; 367x122x95 in – 7040 lb; 445x122x95 in – 7920 lb

Copyright © 2024 :: ACM Machinery Ltd. All rights reserved. Privacy policy