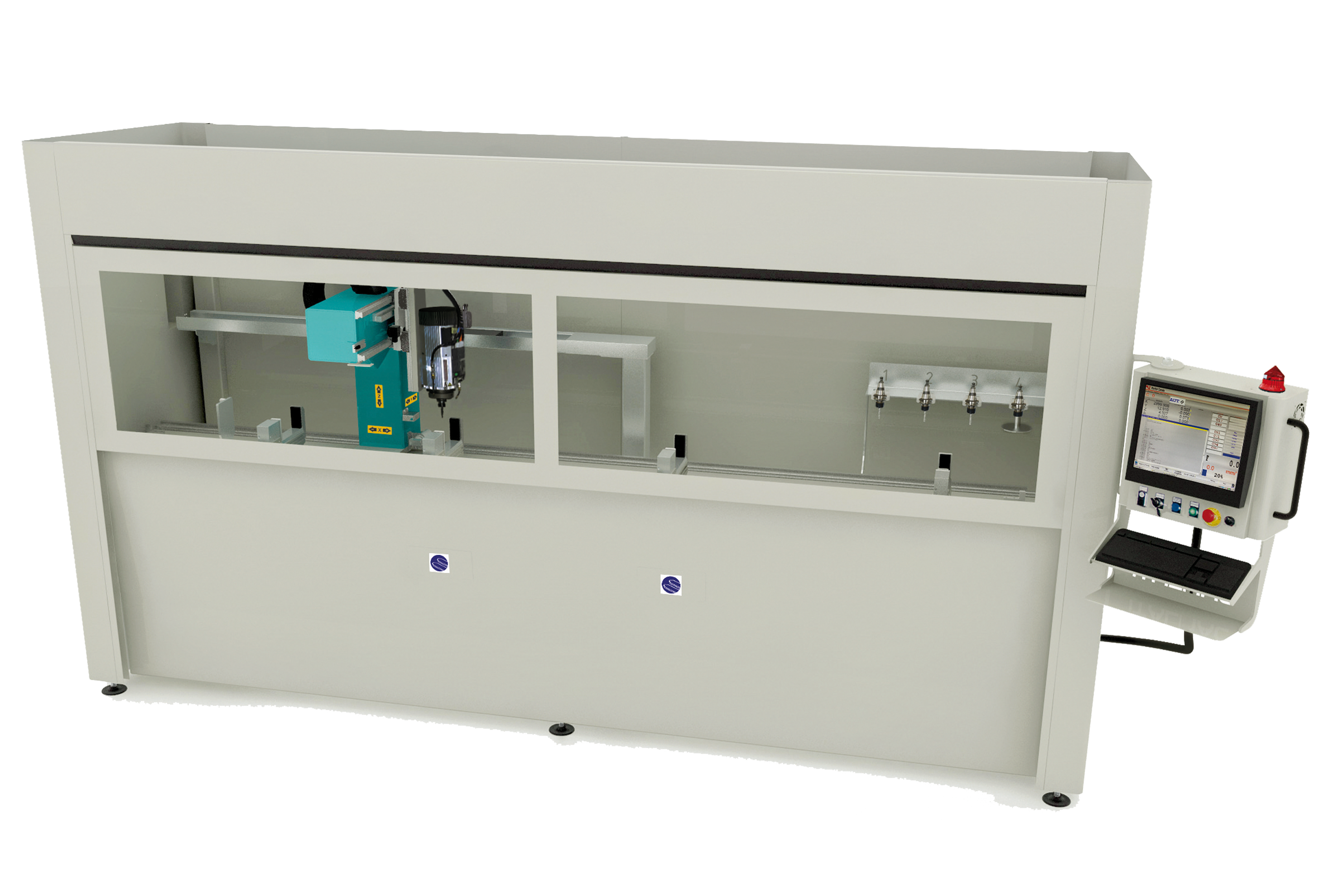

O3 Machining Center

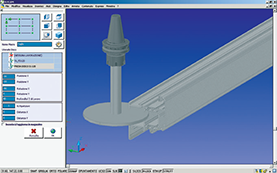

O3 is a 3-Axis CNC machining center with moving portal, especially designed for milling, drilling, threading and cutting bars or workpieces made of aluminium, PVC, light alloys and steel.

Technical Features

- Main structures made of electro-welded steel, normalized and worked with CNC machine tools.

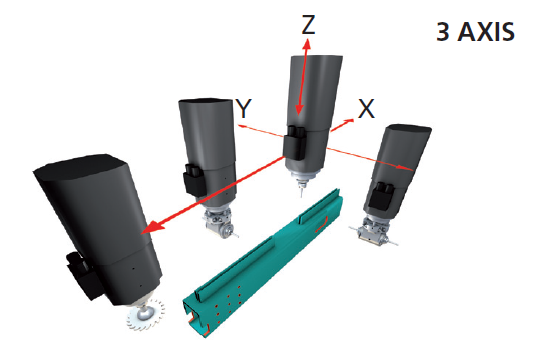

- 3-Axis movement controlled by high-precision brushless servomotors.

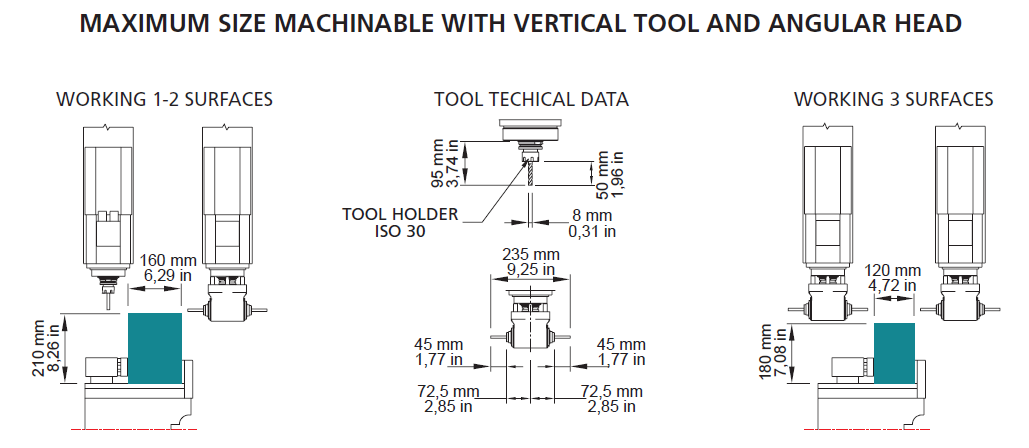

- Electric spindle (4 kW in S1), with ISO 30 tool connection suitable for material removal processes during milling and drilling operations.

- Tool magazine holding up to 5 tools, mounted on the base of the machine.

- Clamps manual positioning (automatic positioning optional).

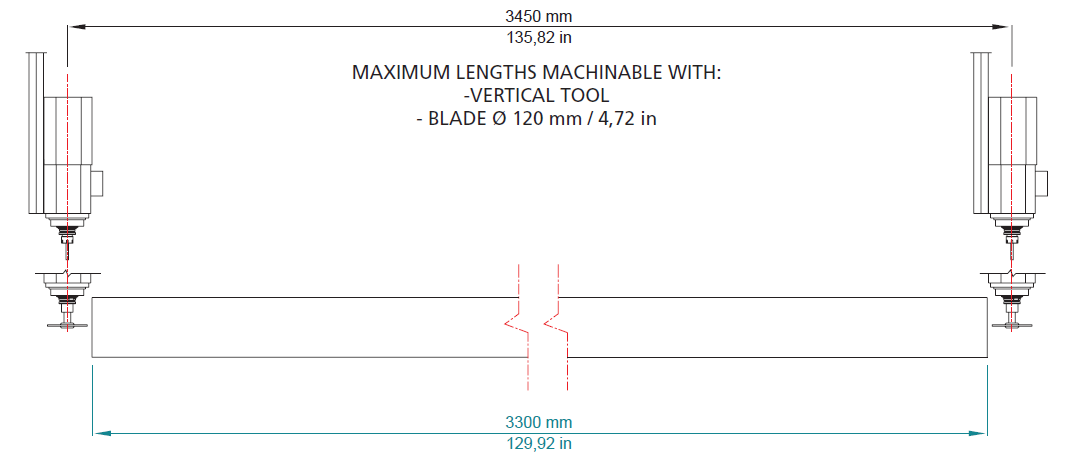

- Maximum workable length 3.3 meters

- Chips conveyor plate

- Full safety enclosure

- Angular head which allows machining operations on the lateral faces of the workpiece without its repositioning

Specifications

- X AXIS LONGITUDINAL: 3450 mm (135.82 in)

- Y AXIS CROSS: 600 mm (23.6 in)

- Z AXIS VERTICAL: 265 mm (10.43 in)

- MACHINING OF THE WORKPIECE SIDES: Angular head

- AXIS ACCELERATION: X 1.5 m/sec²; Y 1.5 m/sec²; Z 2 m/sec²

- AXIS POSITIONING SPEED: X 40 m/min; Y 40 m/min; Z 15 m/min

- TOOL MAGAZINE CAPACITY: 5 positions

- MAXIMUM MILLING BLADE DIAMETER: 120 mm (4.72 in)

- NUMBER OF STANDARD VICES: 4

- VICES POSITIONING: manual (automatic optional)

- NUMBER OF STOP REFERENCES STANDARD: 1 manual

- VOLTAGE: 400 V triphase – 50/60 Hz

- SPINDLE MOTOR POWER S1: 4 kW (5,5 kW / 7,5 kW optional)

- ADJUSTABLE ELECTRO SPINDLE SPEED: 0-18000 rpm (0-24000 rpm optional)

- TOOL HOLDER: ISO 30

- SPINDLE COOLING SYSTEM: Electric fan

- OPERATING PRESSURE: 7 bar

- TOTAL INSTALLED POWER: 6 kW / 8kW

- OVERALL DIMENSIONS (DxWxH) mm – WEIGHT kg: 4600x1675x2260 mm – 1400 kg

- OVERALL DIMENSIONS (DxWxH) in – WEIGHT lb: 181.1x66x89 in – 3080 lb

Copyright © 2024 :: ACM Machinery Ltd. All rights reserved. Privacy policy