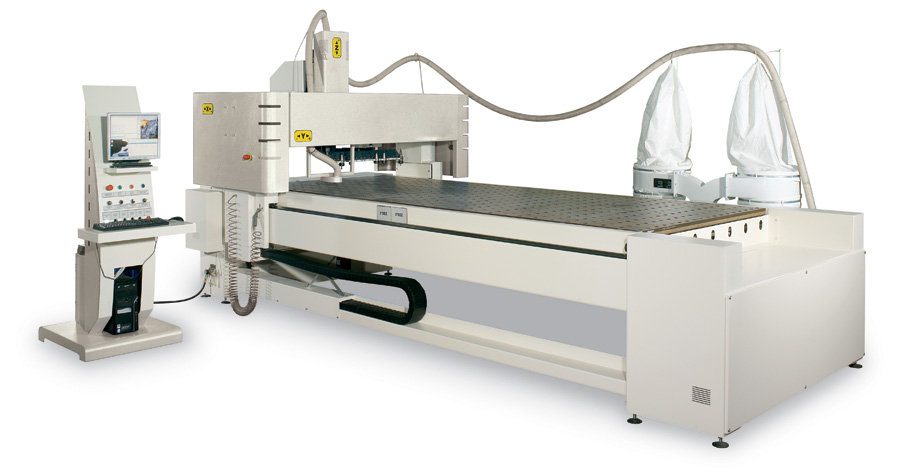

AluBond 3100

3 Axis Machining Center for Aluminum Composite Panels

The AluBond 3100 machining center for aluminum composite panels is designed with the highest efficiency in mind. From its easy to use software to its robust base and gantry, this machining center will make light duty of all your composite panel fabrication. With its eight tool changer, variable speed spindle, large milling capacity and dust extraction, this unit is well detailed for your specific applications.

Technical Data

- Milling capacity: X=3100 Y=1550 Z=260

- Spindle speed: 2800 to 20000 rpm

- X, Y and Z Axis controlled by CNC

- Two softwares: one for machine movements, tool changes and alarms; and a professional CAD / CAM software, Artcam

- Artcam allows for importation of DXF, Bitmap, etc., as well as, a powerful Computer Aided

- Design program, allowing programming directly at the machine controls

- X, Y and Z movements utilize Brushless motors with high precision helical gears and rack

- Working table height:1000 mm

- Spray mist lubrication

- Automatic tool changer with 8 positions

- Tool diameter compensation software

- Electro spindle with quick tool changer ISO 30: 4,7 KW 6.3Hsp @ 20.000 rpm

- 230/400V 50 Hz

- Working table with vacuum clamping system separated into 4 sectors

- Dust extraction

- Pressure: 7 bar. Air consumption 40 NL/cycle (normal litre/cycle) 2440 cubic inches/cycle

Copyright © 2024 :: ACM Machinery Ltd. All rights reserved. Privacy policy